The manufacturing process of stainless faucet

Stainless steel is a popular material for kitchen and bathroom fixtures because of its durability and ease of cleaning. Stainless steel is also known for its sleek, modern look, which makes it a perfect choice for high-end kitchens and bathrooms. However, the manufacturing process of stainless steel can be complex, which is why it’s important to have a reliable supplier. In this blog post, we will explore the manufacturing process of stainless faucets and how you can ensure that you’re getting the best possible product.

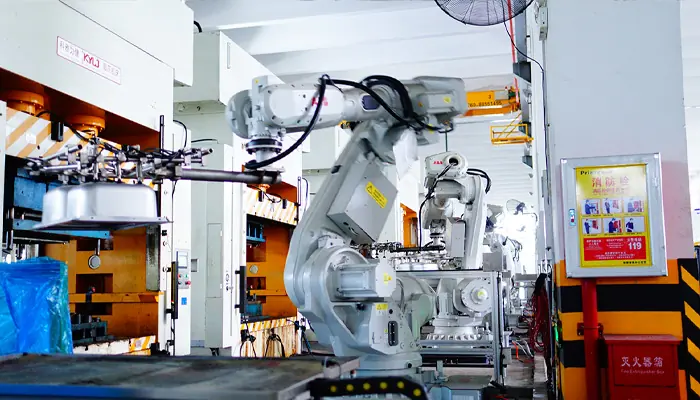

The Manufacturing Process of Stainless Steel Faucets

Stainless steel faucets are made by a manufacturing process that starts with the cold working of metal. This process is done using either a hammer or anvil, and it results in the creation of a variety of shapes for the final product. Once the metal has been shaped, it is heated to a specific temperature which softens it. This allows for easier machining and fabrication processes.

After the metal has been softened, it is machined into its final form. This includes cuts and angles that are necessary for the design of stainless steel faucets. The next step in the manufacturing process is to coat the faucet with a corrosion-resistant finish. This finish helps to protect the faucet from damage and also gives it a uniform appearance.

Another important part of the manufacturing process for stainless steel faucets is the packaging. The faucets must be packaged carefully in order to avoid any damage during shipping or storage. Additionally, they must be properly labeled so that customers can understand what they are purchasing.

The manufacturing process of stainless steel faucets is very complex, so it needs the manufacturers’ higher technology. DALI is the one who has high technology and who is professional and experienced in producing such faucets. If you are finding a reliable manufacturer, it is wise of you to consider DALI.

Conclusion

Stainless steel faucet manufacturing is a process that starts with raw materials, stainless steel, and other metals. The metals are melted down and formed into parts of the faucet such as the flange, spout, and handle. These parts are then machined to specific specs by a specialized company before they are assembled into the final product. After assembly, any additional finishing touches are done and then tested for quality assurance.